Recently, the Key Laboratory of Textile Fibers and Products, Ministry of Education, at our university published a research article entitled "A Liquid Metal-Embedded Sheath-Core Fiber with Internal Helical Structure for Strain-Insensitive Electronics" in Advanced Science (DOI: https://doi.org/10.1002/advs.202509547). Dr. Luo Mengying and master’s student Wei Wanru are the co-first authors, while Professors Wang Dong and Li Mufang are the corresponding authors.

With the rapid advancement of flexible electronics, smart textiles have demonstrated expanding application potential in areas such as health monitoring, human–machine interaction, and wearable devices. Stable electrical conductivity, as a critical performance metric for flexible wearable systems, is essential for ensuring reliable signal transmission, enhancing sensing accuracy, optimizing display performance, and maintaining overall device stability. Nevertheless, achieving simultaneous high elasticity, high conductivity, and outstanding environmental and mechanical stability in conductive materials remains a key scientific challenge that must be urgently addressed in this field.

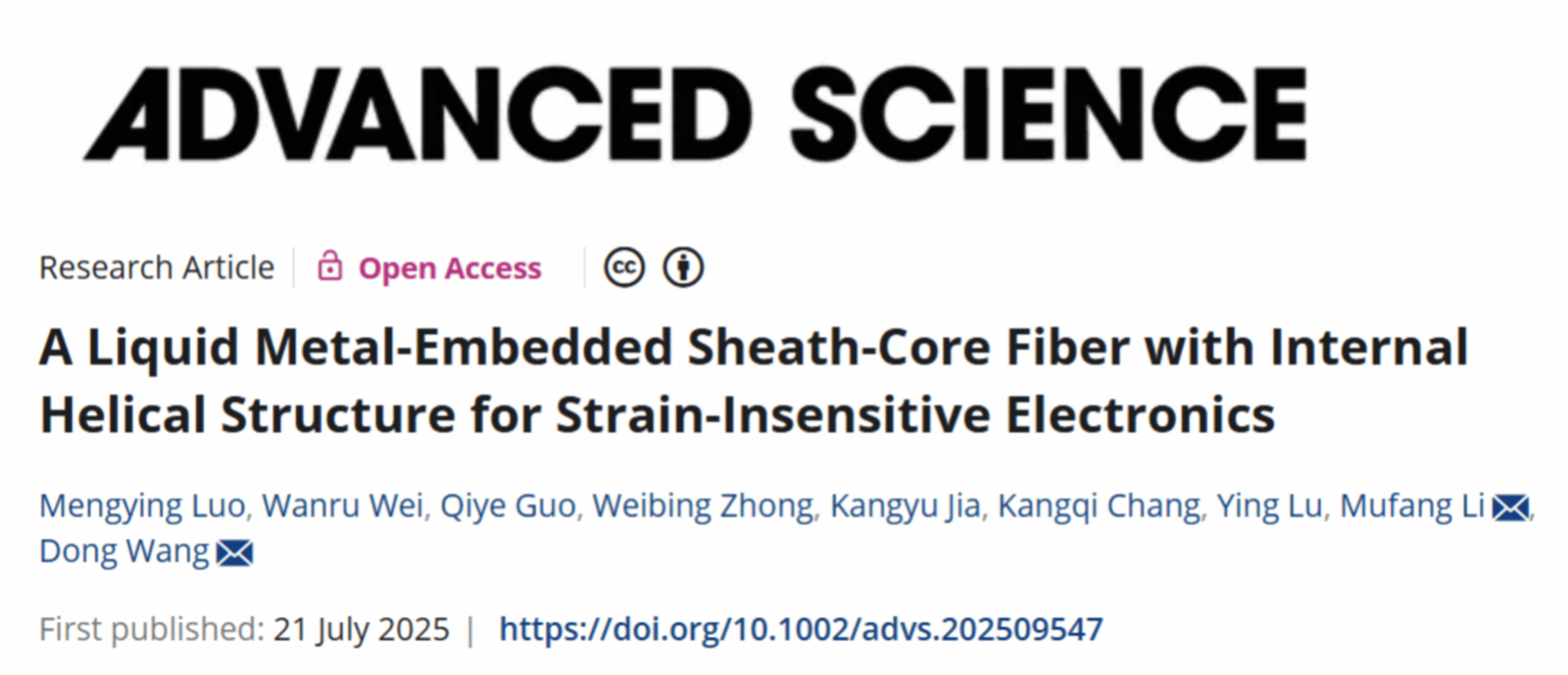

The research group led by Professors Wang Dong and Li Mufang developed a novel fiber fabrication approach based on coaxial wet-spinning technology, enabling precise regulation of the interfacial behavior between inner and outer phase fluids. This strategy allows for controllable morphological transformation of the hollow fiber cavity from linear to wavy and ultimately to a helical configuration. The resulting hollow fibers demonstrate exceptional mechanical performance with an elastic strain capacity reaching up to 1440%, while maintaining compatibility with continuous, large-scale production processes.

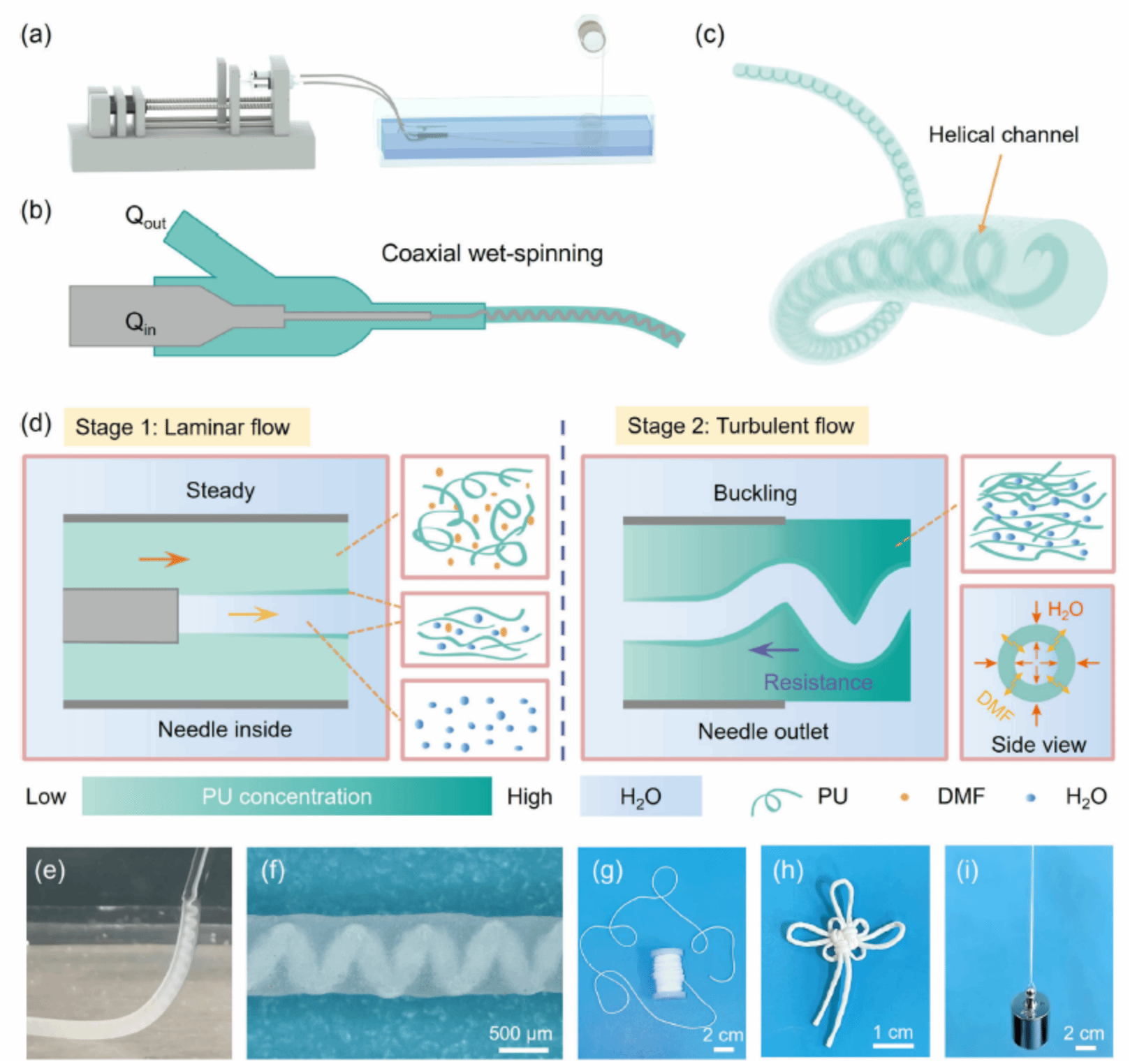

Building upon this structural platform, the team incorporated highly conductive liquid metal into the internal helical cavity. By leveraging the synergistic interaction between the intrinsic elasticity of the matrix material and the geometric resilience of the helical architecture, the fiber achieves remarkable stretch ability, ultra-high electrical conductivity (1.94 × 10⁵ S/m), and outstanding strain insensitivity. The fiber exhibits excellent electromechanical stability: under 100% tensile strain, the resistance change is less than 1.6%, yielding a Q-factor of 62.5; even at extreme elongation of 600%, the resistance variation remains as low as 30%. Furthermore, the fiber maintains stable electrical performance under diverse mechanical deformations, including bending, twisting, and compression.

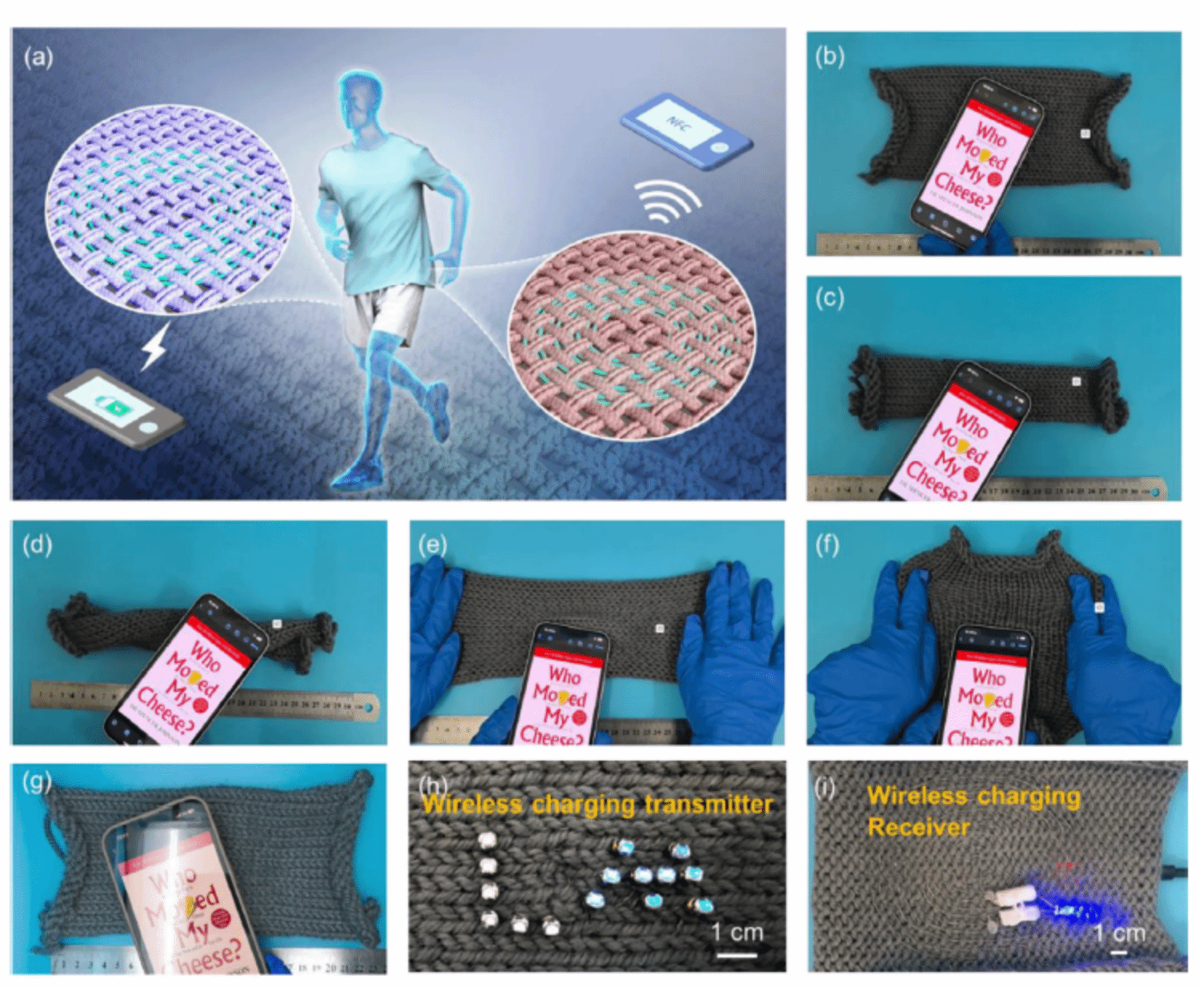

Moreover, this advanced sheath-core fiber can be directly integrated into textile structures through conventional weaving techniques and demonstrates superior functionality in practical applications such as Joule heating, near-field communication (NFC), and wireless power transfer. This work not only overcomes the fundamental limitations of conventional conductive materials in dynamic operational environments but also establishes a new paradigm for the development of weavable, multifunctional electronic textiles. These features open promising avenues for next-generation applications in smart apparel, electronic skin, and wearable medical monitoring systems.

This study was supported by the National Key Research and Development Program of China (Grant Nos. 2022YFB3805801 and 2022YFB3805803).